Introduction to Edge Bleed

Definition and Importance

What is Edge Bleed for Moisture Barriers?

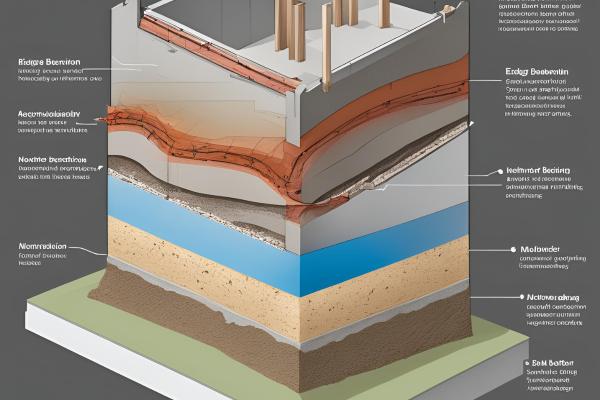

Edge bleed refers to the phenomenon where moisture infiltrates the edges of a barrier system, compromising its effectiveness. This can occur when there are gaps or weaknesses at the edges of a moisture barrier, allowing water to seep through. Understanding edge bleed is crucial for anyone involved in construction or building maintenance, as it directly impacts the integrity and longevity of structures.

Role in Construction

Why Edge Bleed Matters in Building Projects

In construction, moisture barriers are essential for protecting buildings from water damage. Edge bleed can undermine these barriers, leading to serious issues such as mold growth, structural weakening, and material degradation. Addressing edge bleed is vital for ensuring the durability and safety of a building, making it a key consideration in both new construction projects and renovations.

Causes of Edge Bleed

Environmental Factors

Weather Conditions that Contribute to Edge Bleed

Environmental conditions, such as heavy rainfall, high humidity, and temperature fluctuations, can exacerbate edge bleed. These factors increase the amount of moisture that comes into contact with the edges of the barrier, increasing the likelihood of infiltration. Proper design and installation can mitigate these risks by accounting for local weather patterns and environmental stresses.

Material Deficiencies

How Material Quality Affects Edge Bleed

The quality of materials used in moisture barriers plays a significant role in edge bleed. Inferior or improperly applied materials are more likely to develop gaps or weaknesses over time, allowing moisture to penetrate. Ensuring that high-quality, durable materials are used and correctly installed is crucial for preventing edge bleed and maintaining the barrier’s effectiveness.

Identifying Edge Bleed

Signs and Symptoms

How to Detect Edge Bleed in Moisture Barriers

Detecting edge bleed involves looking for signs of moisture intrusion along the edges of a barrier. Common symptoms include discoloration, damp patches, mold growth, and a musty odor. Regular inspections and monitoring are essential for early detection and intervention, preventing more extensive damage and costly repairs.

Inspection Techniques

Methods for Assessing Edge Bleed Risks

Various inspection techniques can be employed to assess the risk and presence of edge bleed. These include visual inspections, moisture meters, infrared thermography, and pressure testing. Utilizing a combination of these methods provides a comprehensive understanding of the barrier’s condition and helps identify areas that require attention.

Impact of Edge Bleed on Moisture Barriers

Structural Integrity

How Edge Bleed Compromises Building Structure

Edge bleed can significantly compromise the structural integrity of a building. Moisture intrusion can weaken construction materials, cause wood rot, and deteriorate metal components. Over time, this leads to structural instability and safety hazards, underscoring the importance of addressing edge bleed promptly.

Moisture Intrusion

Consequences of Edge Bleed on Moisture Control

Moisture control is critical for maintaining a healthy and durable building environment. Edge bleed undermines moisture control efforts, leading to increased humidity levels, mold growth, and indoor air quality issues. Effective moisture barrier design and maintenance are essential for preventing these problems and ensuring a comfortable living or working space.

Preventing Edge Bleed

Design Considerations

Architectural Strategies to Mitigate Edge Bleed

Preventing edge bleed starts with thoughtful architectural design. One of the most effective strategies is to ensure a continuous and uninterrupted moisture barrier. This involves designing overlapping joints and seams that prevent moisture ingress. The use of proper flashing techniques around windows, doors, and other penetrations is crucial. Additionally, incorporating slopes and drainage systems to direct water away from the building envelope can significantly reduce the risk of edge bleed. Regularly reviewing and updating design practices based on the latest industry standards and research is essential to mitigating edge bleed effectively.

Material Selection

Choosing the Right Materials to Avoid Edge Bleed

Selecting high-quality materials is key to preventing edge bleed. Moisture barriers should be made from durable, water-resistant materials that can withstand environmental stress. It is important to choose materials that are compatible with each other to ensure proper adhesion and sealing. Avoiding materials that are prone to deterioration or that may react adversely to environmental conditions is also crucial. Consulting with manufacturers and experts to select the best materials for specific project requirements can help create a robust moisture barrier system.

Repairing Edge Bleed

Assessment and Planning

Steps to Address Edge Bleed Issues

Addressing edge bleed issues begins with a thorough assessment to identify the extent of the problem. This involves inspecting the affected areas, using tools such as moisture meters and infrared cameras to detect hidden moisture. Once the assessment is complete, a detailed plan should be developed to address the identified issues. This plan should outline the necessary repair steps, materials required, and a timeline for completion. Coordination with contractors and specialists may be necessary to ensure the repair work is executed properly.

Repair Techniques

Effective Methods for Fixing Edge Bleed

Repairing edge bleed typically involves resealing or replacing the compromised sections of the moisture barrier. This can include applying new flashing, sealing gaps and seams with appropriate sealants, and reinforcing joints with compatible materials. In some cases, it may be necessary to replace sections of the barrier entirely. Ensuring that repairs are performed meticulously and using high-quality materials is essential to preventing future edge bleed. Regular follow-up inspections can help verify the effectiveness of the repairs and address any emerging issues promptly.

Edge Bleed in Different Types of Moisture Barriers

Vapor Barriers

Edge Bleed Considerations for Vapor Barriers

Vapor barriers are designed to prevent moisture vapor from passing through walls and ceilings. Edge bleed in vapor barriers can compromise their effectiveness, leading to increased humidity levels and potential mold growth. To prevent edge bleed in vapor barriers, it is crucial to ensure a continuous seal around the edges and joints. Using tapes and sealants specifically designed for vapor barriers can enhance the integrity of the installation. Regular inspections and maintenance are also important to address any signs of deterioration or damage.

Waterproofing Membranes

Managing Edge Bleed in Waterproofing Systems

Waterproofing membranes are used to protect structures from liquid water infiltration. Edge bleed in waterproofing membranes can lead to significant water damage and structural issues. To manage edge bleed, it is essential to properly lap and seal the membrane edges during installation. Using compatible adhesives and sealants can help create a watertight seal. Additionally, installing protective layers, such as drainage boards, can further safeguard the membrane and reduce the risk of edge bleed. Ensuring that waterproofing systems are installed according to manufacturer guidelines and industry best practices is critical for their long-term performance.

Case Studies on Edge Bleed

Real-World Examples

Documented Instances of Edge Bleed Issues

Numerous real-world examples illustrate the impact of edge bleed on building performance. In one case, a commercial building experienced significant water damage due to edge bleed in the moisture barrier system. The investigation revealed that improper installation and use of incompatible materials were the primary causes. In another instance, a residential property suffered from mold growth and structural decay due to edge bleed in the vapor barrier. These documented cases highlight the importance of proper design, material selection, and installation techniques in preventing edge bleed.

Lessons Learned

What These Case Studies Teach Us About Edge Bleed

Case studies on edge bleed provide valuable insights into the factors that contribute to this issue and effective prevention and repair strategies. Key lessons include the importance of continuous and compatible moisture barriers, the need for meticulous installation practices, and the value of regular inspections and maintenance. Additionally, these case studies underscore the significance of education and training for architects, contractors, and maintenance personnel to ensure that best practices are followed. By learning from documented instances of edge bleed, industry professionals can enhance their approaches to moisture barrier design and implementation, ultimately improving building durability and performance.

Innovations in Edge Bleed Prevention

New Technologies

Advancements in Materials and Methods

Recent advancements in materials and methods have significantly improved the prevention of edge bleed in moisture barriers. Innovative sealants and adhesives that offer superior flexibility and adhesion are now available, providing more robust protection against moisture intrusion. Additionally, advancements in self-healing materials that can automatically repair minor damages and seal gaps are revolutionizing moisture barrier systems. Modern application techniques, such as spray-applied membranes and automated sealing systems, ensure more consistent and precise installation, reducing the risk of edge bleed. These technologies enhance the overall durability and effectiveness of moisture barriers, setting new standards for building protection.

Best Practices

Industry Standards for Preventing Edge Bleed

The implementation of industry best practices is crucial for preventing edge bleed in moisture barriers. Key standards include ensuring a continuous and uninterrupted moisture barrier, proper overlap and sealing of joints, and the use of compatible materials. Detailed guidelines on flashing installation, drainage systems, and slope design are also essential components of these best practices. Regular training and certification programs for installers and contractors help ensure that these standards are consistently met. Adherence to industry standards not only improves the reliability of moisture barriers but also extends the lifespan of buildings by preventing moisture-related issues.

Future Directions in Edge Bleed Research

Ongoing Studies

Current Research Focused on Edge Bleed Solutions

Ongoing research is exploring various innovative solutions to address edge bleed in moisture barriers. Studies are examining the efficacy of new materials, such as advanced polymers and nanomaterials, that offer enhanced water resistance and durability. Researchers are also investigating the impact of different environmental conditions on edge bleed, aiming to develop more resilient moisture barrier systems. Collaborative efforts between universities, industry leaders, and research institutions are driving these studies, with the goal of finding sustainable and effective methods to mitigate edge bleed.

Emerging Trends

Future Trends in Moisture Barrier Technologies

Future trends in moisture barrier technologies are focused on integrating smart materials and digital monitoring systems. Smart materials with embedded sensors can detect and alert the presence of moisture, allowing for early intervention and repair. Digital monitoring systems that provide real-time data on the condition of moisture barriers are also gaining traction, enabling proactive maintenance and reducing the risk of edge bleed. Sustainable practices, such as the use of eco-friendly and recyclable materials, are becoming increasingly important in the development of moisture barriers. These emerging trends represent the future direction of the industry, aiming to enhance the performance, reliability, and sustainability of moisture barrier systems.

Conclusion

Understanding edge bleed in moisture barriers is crucial for maintaining the integrity and durability of buildings. Edge bleed, caused by factors such as environmental conditions and material deficiencies, can lead to significant structural and moisture control issues. Identifying and addressing edge bleed through regular inspections and proper repair techniques is essential for preventing long-term damage. Advances in materials and methods have greatly improved the prevention of edge bleed, while industry best practices ensure consistent and effective moisture barrier installations. Ongoing research and emerging trends in moisture barrier technologies promise even more resilient solutions in the future. By prioritizing the prevention and management of edge bleed, construction professionals can safeguard buildings from moisture-related problems, ensuring a healthy and stable environment for occupants.

FAQ’s

1. What is Edge Bleed in Moisture Barriers, and Why is It Important?

Answer: Edge bleed is the phenomenon where moisture infiltrates the edges of a moisture barrier system, weakening its effectiveness. This can occur due to gaps or weaknesses along the barrier edges, allowing water to seep through. Understanding edge bleed is essential in construction and building maintenance because it directly affects the durability and integrity of structures, potentially leading to costly repairs.

2. Why is Edge Bleed a Concern in Building Projects?

Answer: Edge bleed poses a significant risk in building projects because it can compromise the protection moisture barriers provide, leading to problems like mold growth, structural degradation, and even material breakdown. Properly addressing edge bleed is vital in new construction and renovation projects to ensure buildings remain safe, durable, and moisture-resistant over time.

3.What Causes Edge Bleed in Moisture Barriers?

Answer: Edge bleed can be caused by a variety of factors. Environmental conditions, such as heavy rain, high humidity, and temperature changes, can exacerbate edge bleed by increasing the exposure of barrier edges to moisture. Additionally, poor-quality materials or improper installation can lead to weaknesses or gaps, allowing moisture to penetrate the barrier system. High-quality materials and careful installation practices are crucial in reducing edge bleed risks.

4. How Can Edge Bleed Be Detected in a Building?

Answer: Detecting edge bleed involves inspecting the barrier edges for signs of moisture infiltration. Symptoms may include discoloration, damp spots, mold, and musty odors. Building professionals often use tools like moisture meters, infrared thermography, and pressure testing to identify and measure edge bleed. Regular inspections are key to spotting and addressing edge bleed issues early, helping to avoid extensive repairs.

5.What Methods Are Available to Prevent Edge Bleed in Moisture Barriers?

Answer: Preventing edge bleed starts with thoughtful design and the use of high-quality materials. Moisture barriers should be continuous, with overlapping seams, proper flashing around openings, and drainage systems to direct water away. Material selection is critical, as compatible and durable materials help create a reliable barrier. Industry standards also emphasize regular inspections and maintenance to uphold the barrier’s integrity and address any developing issues.